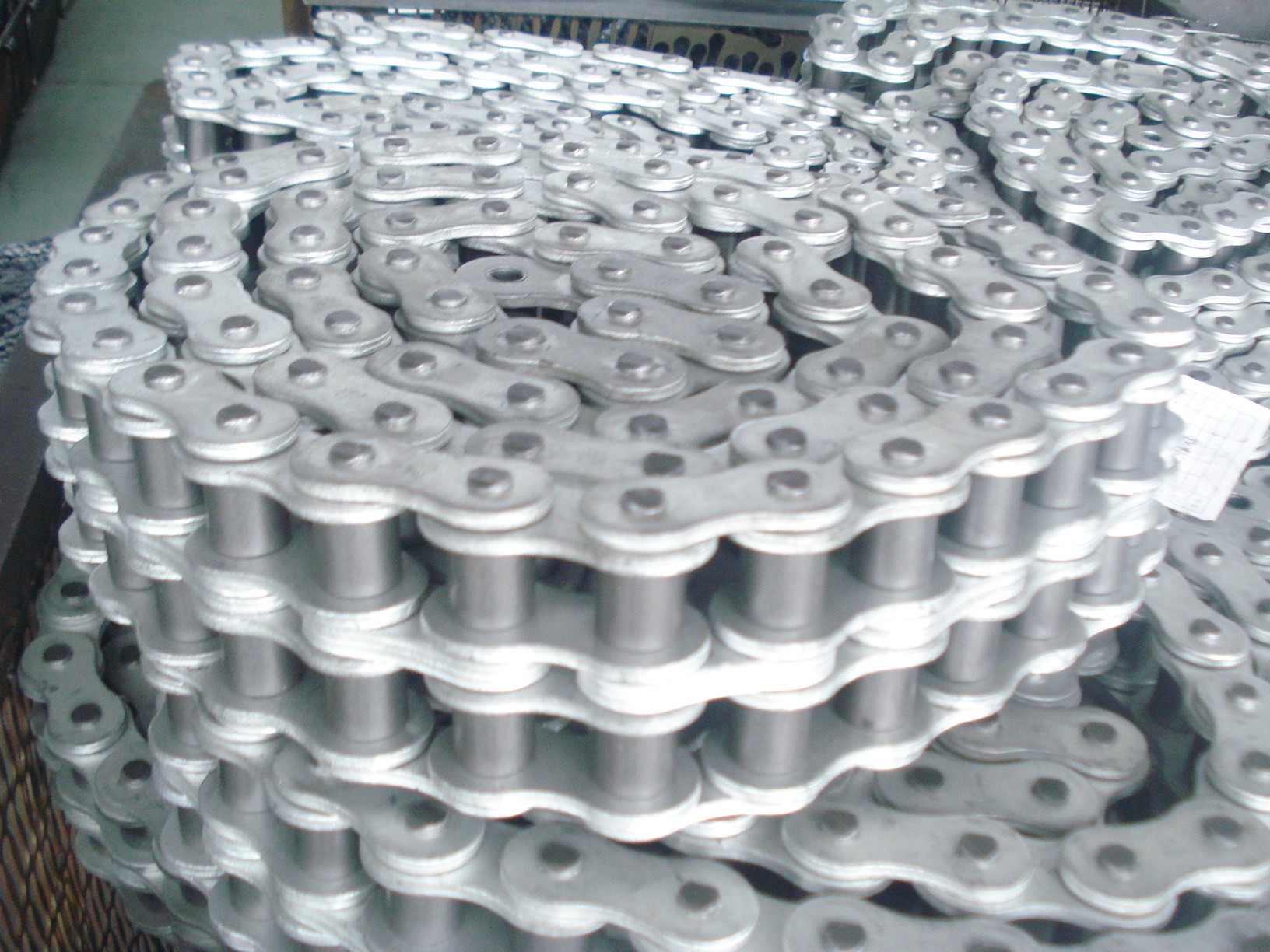

Dacromet Plated Chain

Dacromet Plated Chain

● Dacromet-coated transmission chains comply with international authoritative standards such as ISO, ASME/ANSI, DIN, and JIS. They mainly include series like high-corrosion-resistance Dacromet-coated transmission chains, wear-resistant Dacromet-coated transmission chains, and low-temperature-resistant Dacromet-coated transmission chains, which can meet the application scenarios under strong corrosion, high dust, and harsh climate conditions;

● High-strength alloy structural steel is used as the base material. After precision forging and integral heat treatment strengthening, a uniform protective coating with strong adhesion is formed on the surface through the Dacromet coating process (zinc-chromium coating technology). The products feature super strong corrosion resistance, excellent high-temperature resistance, and good wear resistance. Among these properties, the tensile strength is more than 1.2 times the minimum tensile strength specified in ISO standards, and the corrosion resistance duration in the neutral salt spray test can reach more than 1000 hours, which is far superior to ordinary chains and chains with conventional coatings;

● The products are widely used in fields such as the automobile manufacturing industry (e.g., automobile chassis transmission systems, engine auxiliary transmission components), marine engineering equipment (e.g., marine platform conveying machinery, ship deck transmission devices), and municipal engineering machinery (e.g., road sweeper transmission systems, sewage treatment equipment transmission components). They can stably transmit power for mechanical equipment under strong corrosion, high load, and outdoor harsh working conditions, ensuring long-term efficient and low-maintenance operation of the equipment.