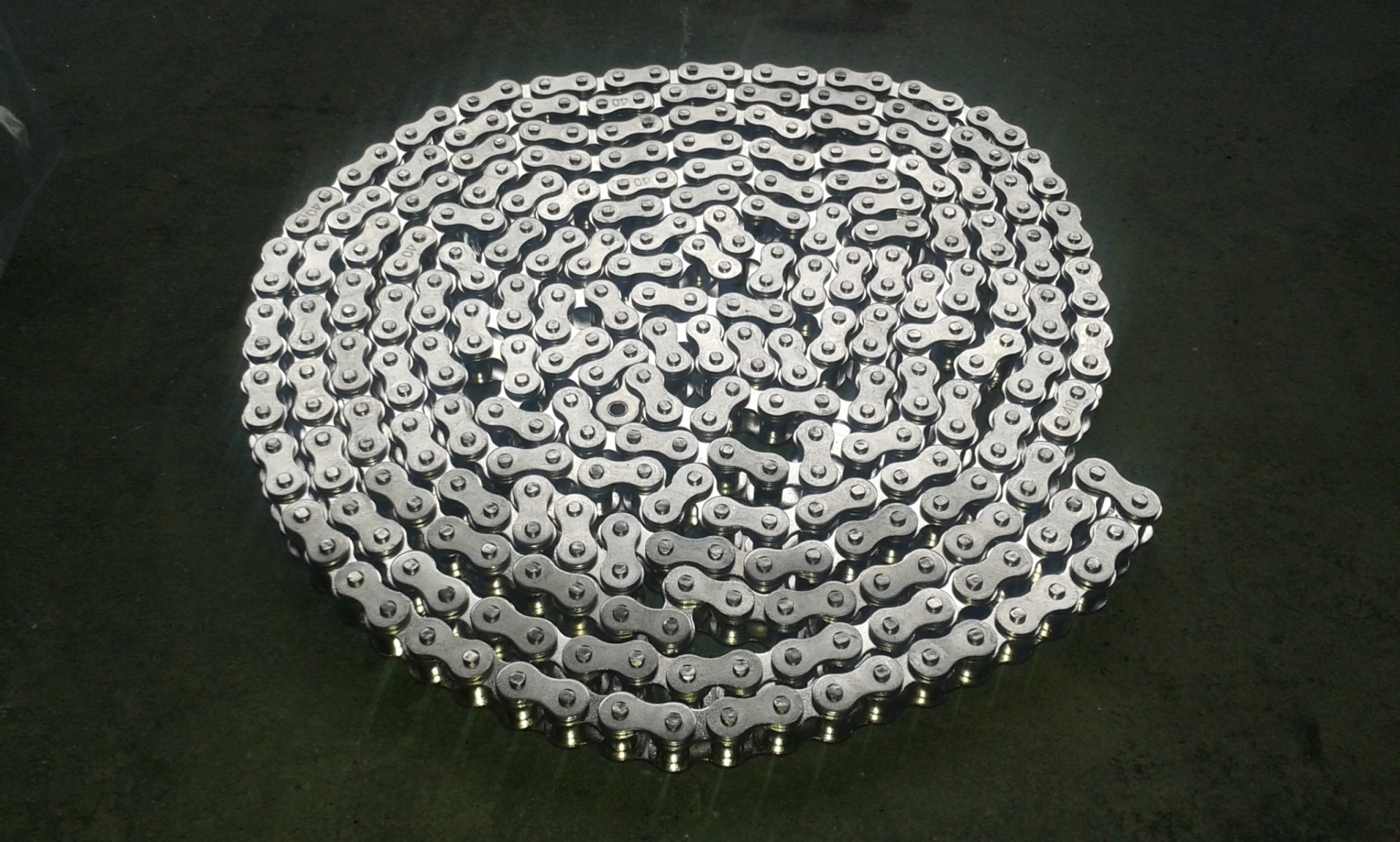

Nickel-plated chain

Nickel-plated chain

● Nickel-plated chains comply with international authoritative standards such as ISO, ASME/ANSI, DIN, and JIS. They mainly include series like high-brightness nickel-plated roller chains, thickened nickel-plated roller chains, and high-temperature-resistant nickel-plated roller chains, which can meet the application scenarios requiring high cleanliness, medium-corrosion environments, and high appearance standards;

● High-quality alloy structural steel is used as the base material. After precision stamping and heat treatment strengthening, a uniform and dense nickel plating layer is formed on the surface through the electrolytic nickel plating process. Combined with sealing treatment technology, the products feature excellent rust and corrosion resistance, high surface finish, and good scratch resistance. Among these properties, the tensile strength is more than 1.1 times the minimum tensile strength specified in ISO standards, and the corrosion resistance duration in the neutral salt spray test can reach more than 500 hours, which is far better than that of ordinary chains;

● The products are widely used in fields such as food packaging machinery (e.g., pastry packaging machines, beverage filling line transmission systems), medical equipment (e.g., small-scale drug sorting machines, laboratory transmission devices), and electronic equipment manufacturing (e.g., circuit board conveyor lines, precision instrument transmission components). They can stably transmit power for mechanical equipment in clean, slightly corrosive environments and those with appearance requirements, ensuring high-precision and low-failure operation of the equipment.