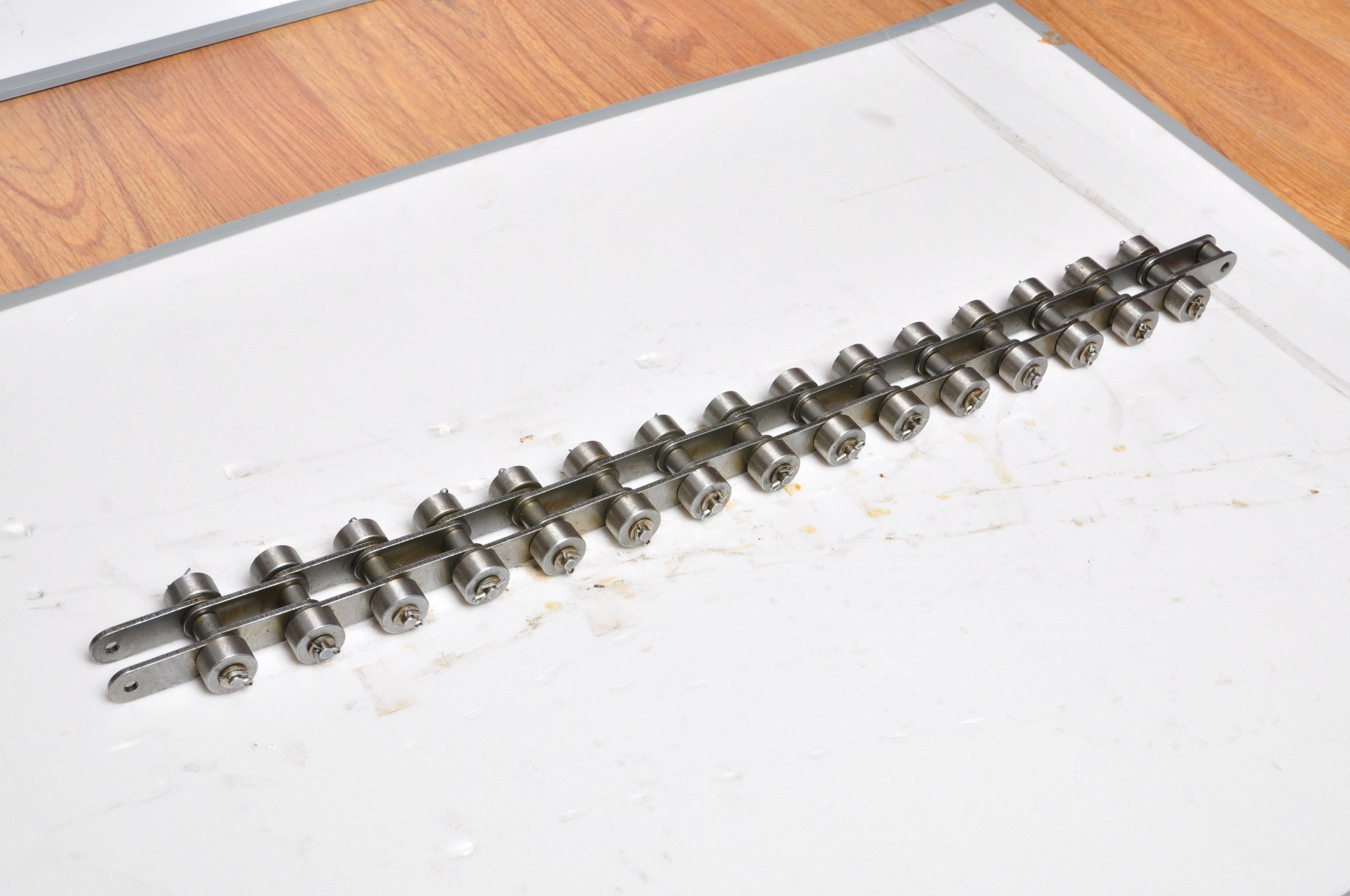

Steel roller multi-speed chain

Steel roller multi-speed chain

● Steel roller multi-speed chains comply with international standards such as ISO, ASME/ANSI, DIN, and JIS, and mainly include series like high-precision steel roller multi-speed chains, heavy-duty steel roller multi-speed chains, low-noise steel roller multi-speed chains, and corrosion-resistant steel roller multi-speed chains, which can meet the conveying needs of complex industrial scenarios requiring multi-gear speed adjustment, high load-bearing capacity, and stable transmission;

● The chain body is made of high-quality medium-carbon alloy steel, and the steel rollers are processed through precision forging, integral quenching and tempering, and surface grinding. Combined with reinforced chain pins, anti-loosening connecting structures, and anti-rust coating (galvanizing or chrome-plating) processes, the products feature excellent wear resistance, strong load-bearing capacity, and flexible speed switching. The surface hardness of the steel rollers reaches HRC 55-60, the maximum allowable load is 1.5 times that of ordinary multi-speed chains, the speed adjustment range covers 0.8-8 m/min, and the speed switching response time is less than 0.3 seconds;

● The products are widely used in heavy industry conveying equipment (e.g., mine ore grading and conveying lines, steel plant auxiliary material transmission chains), automobile manufacturing workshops (e.g., auto parts multi-station processing conveying systems, finished vehicle inspection and transfer lines), and logistics heavy-load sorting centers (e.g., large parcel multi-speed sorting chains, heavy cargo turnover conveying systems). They can adapt to the speed requirements of different processing links or sorting procedures, stably convey heavy or large-sized materials, and ensure the continuity and efficiency of industrial production and logistics operations.